Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

상표: DoHform

원산지: 중국

형성 방법: 펀칭 금형

제품 자료: 금속, 강철, 알류미늄, 철, 구리

제품: 차량 곰팡이, 가정 기기, 가정용 제품

포장: 표준 수출 나무 상자 포장, 훈증 과정 (필요시)

수송: Ocean,Land,Air

원산지: 중국 곤산

포트: Shanghai,Ningbo,China

지불 유형: L/C,T/T,Western Union

인 코텀: FOB,CFR,CIF,EXW

맞춤형 정밀 판금 스탬핑 금형 경험

금형 설계 솔루션

금형 제작 전에 고객의 도면을 분석하고 필요한 경우 설계 변경 솔루션을 제공합니다. 금형 설계는 각 금형 제작 전에 승인을 위해 전송됩니다. 당사의 모든 공구는 강성 DME 및 Hasco 금형 표준에 따라 제작되었으며 Uddeholm 및 International 금형 강 (P20, H13,2344,420, S-7,718H, S136 등) 과 같은 회사의 고급 금형 강만 사용합니다. 핫 러너 시스템의 경우 MoldMaster, DME, Husky, Yudo 등을 사용합니다.

2D + 3D 도면 디자인 :

|

Product name |

11 years experience custom precision sheet metal stamping mould maker |

|

Tooling steel material |

Depend on product, we help customer to choose the suitable material. Commonly used material as below: Carbide(CD650,V3,KD20), ASP-23, ASP-60, S55C---45#55, SKD11. |

|

Steel of mold base |

Depend on product, we help customer to choose the suitable material. Commonly use S45C. |

|

Mould Standard components |

HASCO, MISUMI, Meusburger, DME, etc. |

|

Die concept |

2-Plate Die, 3-Plate Die, Module Die |

|

Mold life |

Depends on the steel material and your requests. Commonly used: 50 Million to 300 Million Times |

|

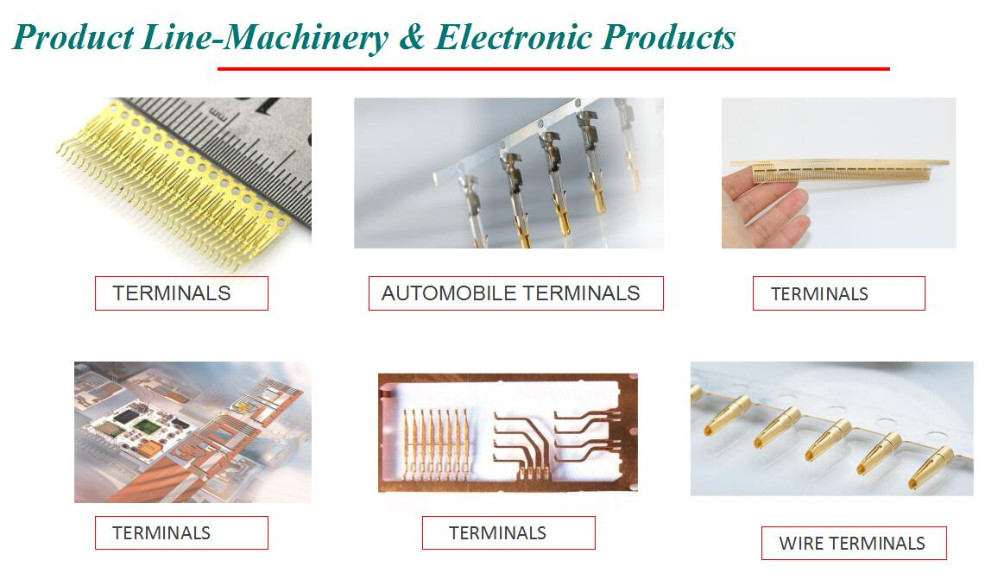

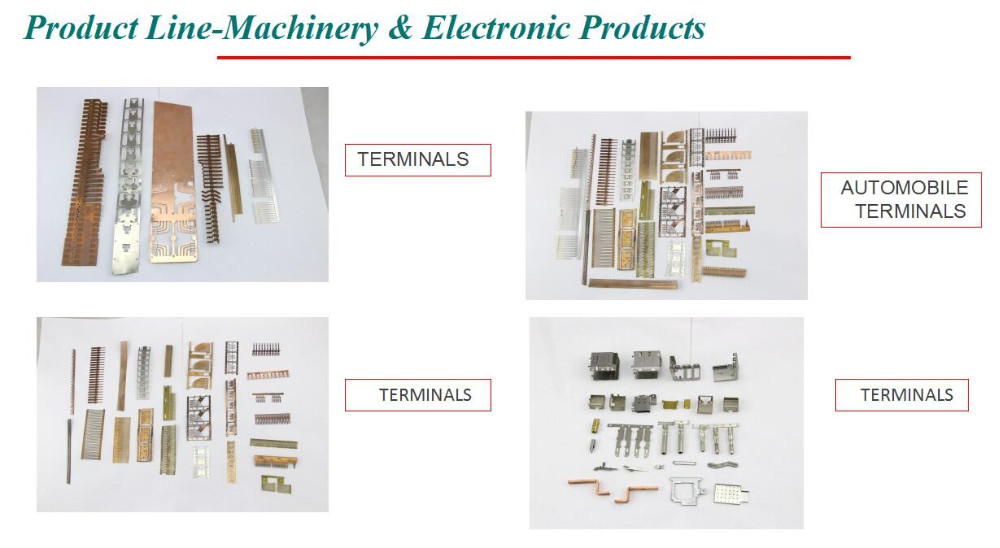

Stamping Product |

PC Terminal, Power terminal, Press-Fit Terminal, Lead frame, SIM Spring, Connector Shield, Battery, Metal USB shell, custom stamping. |

|

Surface finish |

Depends on your requirements. Commonly: Texture Hatching, EDM Hatching, plating, Polishing, Diamoud Polishing, Mirror Polishing and so on. |

|

Delivery time |

Depends on the size and structure. Normally: 25-30 working days after 50% down payment. |

|

Terms of payment |

T/T, L/C, Western Union, D/A, D/P, Paypal. |

|

Machine center |

High speed CNC, Wire cutting, EDM, Grinder, Great Grinder, CNC milling, Drilling and milling, Stamping punching machines, injection machine, Inspection. |

|

R&D |

1. Drawing design and making for products and mold; 2. Mold drawing revising; 3. Production time and quality control in each machining process. (Our own EPR system). |

|

Production |

Pilot Run production and molding production can be provided. |

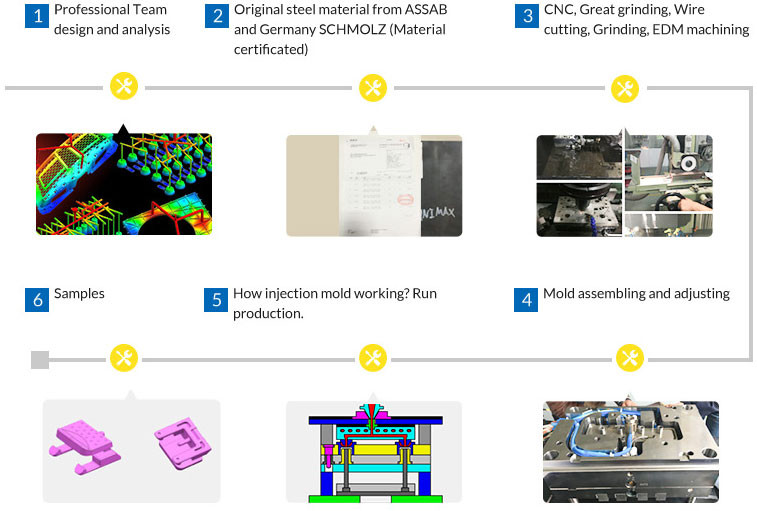

제품 흐름

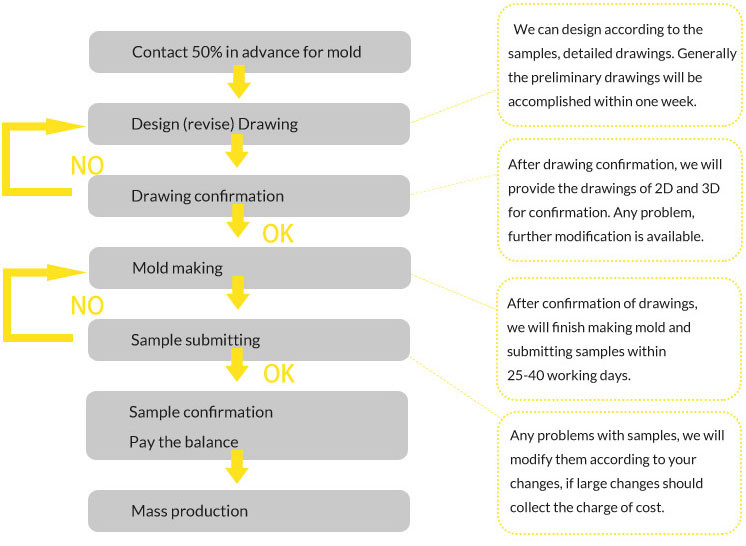

금형을 사용자 정의하는 방법?

A) 판매 서비스 전

B) 생산 기간 서비스

C) 애프터 서비스

파트너

스탬핑 제품

제품 디렉토리 : 프로그레시브 스탬핑 다이 > 판금 스탬핑 부품

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.