Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

상표: DoHform

원산지: 중국

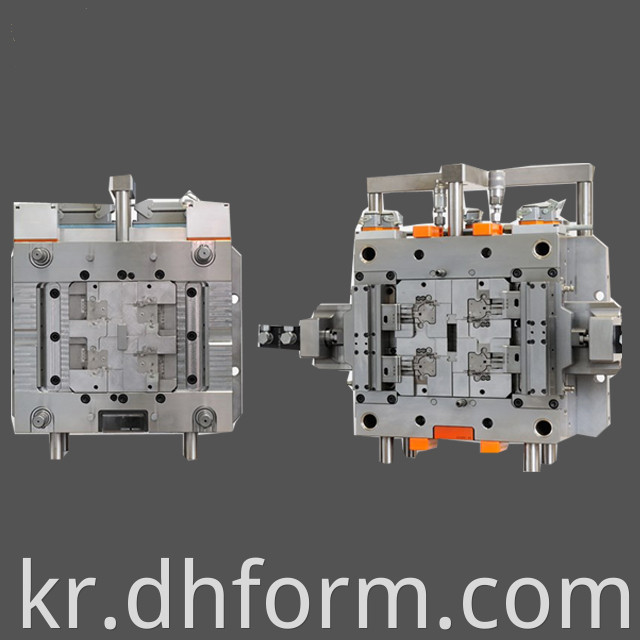

형성 방법: 플라스틱 사출 금형

제품 자료: 탄성 고무, 플라스틱

제품: 차량 곰팡이, 가정 기기, 가정용 제품

포장: 표준 수출 나무 상자 포장, 훈증 과정 (필요시)

수송: Ocean,Land,Air

원산지: 중국 곤산

포트: Shanghai,Ningbo,China

지불 유형: L/C,T/T,Western Union

인 코텀: FOB,CFR,CIF,EXW

전기 디지털 플라스틱 부품 성형

전자 제품 / 자동차 제품을위한 중국 공장 플라스틱 주입 공구

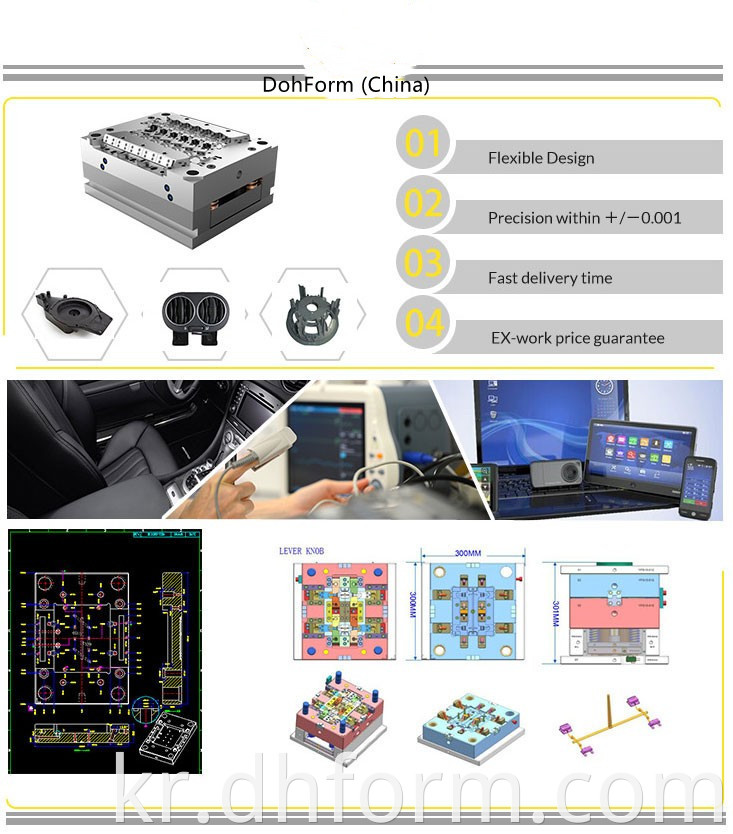

1. 부품 설계 분석에서 시작합니다.

2. 금형 설계 도면 및 DFM 보고서를 사용할 수 있으므로 금형 제작 전에 금형 상태를 확인할 수 있습니다.

3. 제품이 복잡한 경우 Moldflow 보고서도 표시됩니다.

4. 실내 작업장은 좋은 통제하에 당신에게 고품질을 지킵니다.

5. 일반적으로 금형을 만드는 데 15-60 일이 소요되며 정확한 시간은 디자인의 복잡성에 따라 다릅니다.

|

Product name |

Plastic injection molded parts for electrical components |

|

Plastic material |

PP, PPA, ABS, PE, PC, POM, HDPE, etc. |

|

Steel of cavity and core |

Depend on product, we help customer to choose the suitable material. Commonly used material as below: SCHMOLZ: P20HH, 2738, 2083H,2343, 2344, etc. DIN: 1.2738,1.2083, 1.2343, 1.2344, 1.3343, etc. AISI: P20, H13, D2, D6, M2, etc. ASSAB: 718HH, Nimax, 8402, 8407, XW-10, XW-5, EM2, etc. Japanese: HPM2, NAK80, SKD61, SKS3, SKD11, DC53, SKH51, etc. |

|

Steel of mold base |

Depend on product, we help customer to choose the suitable material. Commonly use S45C. |

|

Mould Standard components |

HASCO, MISUMI, Meusburger, DME, etc. |

|

Runner |

1.Hot Runner: (Synventive from Netherland) or as your requests. 2.Cold Runner. |

|

Mold life |

Depends on the steel material and your requests. Commonly used: 1. 300,000-500,000 shots for 1 year under normal use prodcedure for pre-hardness steel material. 2. 5.00,000 shots for 1 year under normal use prodcedure for heat treatment steel material. |

|

Surface finish |

Depends on your requirements. Commonly: Texture Hatching, EDM Hatching, Polishing, Diamoud Polishing, Mirror Polishing and so on. |

|

Delivery time |

Depends on the size and structure. Normally: 25-30 working days after 50% down payment. |

|

Terms of payment |

T/T, L/C, Western Union, D/A, D/P, Paypal. |

|

Machine center |

High speed CNC, Wire cutting, EDM, Grinder, Great Grinder, CNC milling, Drilling and milling, Stamping punching machines, injection machine, Inspection. |

|

R&D |

1. Drawing design and making for products and mold; 2. Mold drawing revising; 3. Production time and quality control in each machining process. (Our own EPR system). |

|

Production |

Pilot Run production and molding production can be provided. |

제품 흐름

금형을 사용자 정의하는 방법?

제품 디렉토리 : 플라스틱 사출 금형 > 플라스틱 소비자 전자 부품 금형

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.